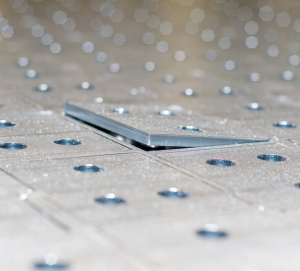

Compared to traditional heat cutting methods, laser cutting in Toronto provides faster and more accurate results. It is a technique of precisely cutting different materials such as wood, plastics, and metals with the use of a high-powered and very concentrated laser beam. The most widely used laser is the CO2 laser which works using a mixture of carbon dioxide gas. It functions by emitting a laser beam onto a specific point on the surface of the material to be cut. How the laser cutting machine operates depends on the program created through the CNC machine.

The applications of CO2 laser cutting in Toronto are almost endless. One of its biggest advantages is that it can accurately cut most materials, regardless of how big or small or intricate the shape may be, producing the least amount of waste possible. Also, there are endless options when it comes to customizing the patterns of design to be carved or cut from the material. Moreover, there are a lot of different techniques that can be utilized for CO2 lasers in order to attain varied results. These include the two major ones below:

Raster laser engraving

In this technique, the laser cutter works in the same way as to how an inkjet printer operates, with the laser moving from end to end while turning on and off very quickly. In other words, it works as an infill engrave which gives the material a sealed vector shape.

Vector laser cutting

This technique of CO2 laser cutting is often programmed into a CNC machine that produces the line or template, which the laser cutter follows. It can create a full incision through the surface of the material being cut.

Ultimately, laser cutting in Toronto gives you the liberty to modify the elements of your design without so much hassle. It can be simply done by changing the programming without having to use another set of tools. If you have yet to find a reliable laser cutting service, 4 Way Metal is the perfect solution. Call us today to learn more about our services.