Metal fabricating is used to make countless products, pieces, parts and component throughout North America. Metal fabrication at an expert shop includes CNC and conventional machining processes like forming, cutting, and finishing.

Metal fabricating services provide countless industries with the materials, parts and tools needed to meet modern demands.

Metal fabricating is generally used in the manufacturing industry, particularly in assembly, computers, medical equipment, appliances, and electronics. Eeverything that contains metal will go through some of the processes of fabrication at some stage. These can include:

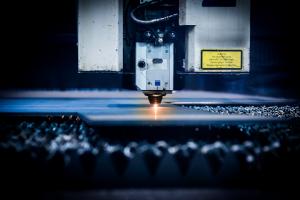

Cutting can involve a few different ways to cut metal:

- Abrasive cutting, in which a saw or grinder is used to cut the material at hand.

- EDM or electrical discharge machining, which melts conductive materials by using a charged electrode spark.

- Shearing, where a cutting tool applies shear stress to make smaller cuts out of bigger pieces of materials.

- Laser cutting is often the most precise and efficient method for cutting, often aided by automated controls.

Forming will shape the component according to the purpose and design of the project. Forming includes some techniques such as:

- Stamping produces an often customized branding design stamped onto the metal.

- Bending can be done manually, with conventional methods or with modern machinery to create the desired form.

- Rolling ensures the dimensions of sheet metal and other materials.

- Welding uses heat to join different pieces of metal together.

- Punching creates holes into the metal surface, often needed for components in electronics or machinery.

Finishing includes polishing or sharpening to get rid of rough edges and spots, and is a crucial step in assuring quality. Finishing process may also involve rinsing and cleaning the metal before delivering a finished product.

Learn more about customized metal fabricating in our modern facility: contact or visit 4 Way Metal today to speak with the experts about your project or business.