Although dependent on the complexity of projects being undertaken and the nature of your desired end product, there are various tools you need when building a mini-fabrication kit for your home. It’s no secret; every home needs a mini workshop where minor metal fabrication projects can be handled. It might be that grilled window that needs to be removed or the nails whose heads need to be chopped.

Conventional powder coating practices are best known for their outlasting performance over competing techniques. This is due to the multiple benefits you can achieve by powder coating your machinery.

Like other businesses, metal fabrication costs can be indexed as a matrix of the source materials, machining and fabrication costs and the finishing expenses among others. The costs present a critical part of the equation for valuing fabrication expenses related to a given project. As an integral part of the manufacturing process, it defines the sale price of the Original Equipment Manufacturers (OEM) products. Metal fabrication Ontario services within the OEM category have over the years presented the costing equation in form of four critical components as below...

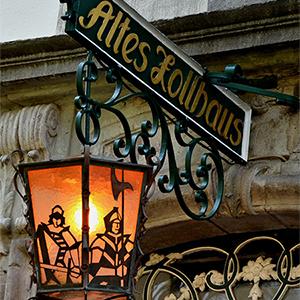

Today, you can see a lot of things that are made of metal. The material has been widely used because of its versatility. Throughout history it has had its part to play, so let's take a look at how it's been used in the past compared to modern day.

Some may not know that the popular word laser is in reality an acronym for Light Amplification by Stimulated Emission of Radiation. A laser produces a highly concentrated light beam that can be used to apply quick energy even to a miniature area. Laser cutting in Toronto has many advantages, and apart from just cutting, they perform other tasks too, of which engraving is one. The lasers offer a whole lot of cutting configurations, no tooling charges and precision cutting of sheet metal. Accuracy is far more consistent than with traditional cutting methods, and as a non contact procedure, fragile parts aren't damaged.